Improved CFD Simulation of Free Radical Polymerization in a Flow Microreactor with Additional Reaction Steps

The complete modelling of free radical polymerization (FRP) in a flow microreactor is dependent upon various transport processes - mass, momentum and heat transfer alongwith chemical reaction. And top of that, all processes are coupled to each other thus making modelling and simulation of this process extremely complex. Over the years, researchers have used various assumptions to simplify the model and thus making simulation manageable enough to give acceptable results. These assumptions are:

1. Single phase newtonian fluid same as water

2. Constant thermo-physical properties (TPP) (density, viscosity, specific heat, thermal conductivity, diffusion coefficient)

3. No gel/glass/cage effect.

These assumptions are reasonable under the conditions of large solvent ratio, low conversion, high Peclet number and high temperature operation. But extending this model to other conditions will not give satisfactory results in existing form which limits the usefulness of modelling and simulation of FRP especially to evaluation of various types of microreactors. Garg et al. 2020a,b have already shown the importance of modelling variable TPP on results compared to constant TPP both in the case of unmixed and mixed feed to the reactor. But Diffusion coefficient of various chemical species were still considered constant and various kinetic rate coefficients were modelled as function of temperature only.

In our current work, for the first time, we are modelling and simulate the variation of the diffusion coefficients and various kinetic rate coefficients based on AK model to cover gel, glass and cage effect in addition to variable TPP. The results will be validated against the experimental data of Iwasaki and Yoshida 2005, and Iwasaki et al. 2006.

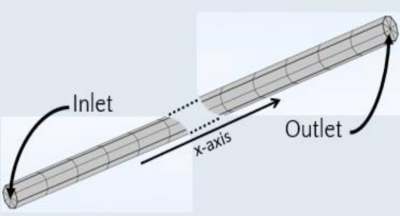

The geometries considered are straight tube and helical coil. Various modules of Comsol are used to solve this problem. Laminar flow and heat transfer module are used to simulate flow and temperature variation in flow microreactor. Different chemical species (5 nos) are modelled using respective CD equations. The source terms of these equations contain the rate equation terms for respective chemical species. To properly model the reaction along the flow, CD equations of these chemical species need temperature and velocity terms from laminar flow and heat transfer modules. Kinetic rate coefficients and diffusion coefficients for different chemical species are calculated using code in Matlab and these values are linked with Comsol using Livelink with Matlab. Multicore preferences are selected to best utilize the capability of parallel processing during simulations.

This will enable a single simulation to be enough to cover all ranges of variations required for FRP in microreactor to give physically reasonable results. This will greatly help to evaluate various microreactors for FRP under various operating conditions and their subsequent optimization

Download

- Dhirag_7161_Poster.pdf - 0.22MB