Modelling the Composition Gradient in Ni-Mn-Ga Single Crystal Grown by Floating Zone Method

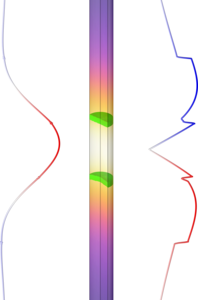

Re-crystallisation of Ni-Mn-Ga Heusler alloys in a floating zone (FZ) optical furnace is a complex problem that depends not only on the compositions of the master alloy and a seed crystal but on the growth speed and evolution of the molten zone shape during the crystal growth process. We have employed COMSOL Multiphysics® and the Heat Transfer Module to simulate the thermodynamics of the FZ crystal growth process, to calculate the macroscopic chemical segregation and therefore composition variation in the resulting ternary Ni-Mn-Ga single crystals. The chemical composition calculations are based on the Scheil-Gulliver equation and the liquification-solidification fractions are extracted from the phase-change material node of the Heat Transfer Module. In the generally adopted and widely studied Bridgman–Stockbarger method the whole of the master alloy is molten, and the shape of the molten zone can be approximated by its length decreasing steadily during the growth process. However, the disadvantage of the Bridgman–Stockbarger method is that the composition variation gradient is unavoidable which results in a large discarding volume of the grown ingot due to unacceptable deviation of the chemical composition from the target values. The floating zone method is chosen to minimise the size of the molten zone during the crystal growth process, which results in the rapid saturation of the melt and thus after a certain grown length the composition gradient tends to zero in a ‘steady state’ region of the ingot. X-ray fluorescence analysis is used to measure the chemical compositions of the seed, master alloy and the grown single crystal. From this data we derive partition coefficients and use these as the inputs for the chemical composition calculation. We found that the composition variation deviated from the simplistic calculation using typical assumptions of the Sheil-Gulliver equation, where a fixed molten-zone size is assumed. Using realistic thermal-conductivity and radiative emission parameters, our COMSOL Multiphysics® simulation modelled the size variation of the molten zone during a fixed-power crystal growth experiment. To our surprise the calculated composition along the crystal, taking into account this molten-zone size change, closely matches the experimental data. We are pleased to conclude that our simulation model based on the COMSOL Multiphysics® software can be used to predict the chemical composition of the grown crystals and will be used to tailor the compositions of the seed crystal and master alloy to minimise the amount of the discarded material after the fabrication.

Download

- Musiienko_6471_poster.pdf - 3.68MB